Induction Heating

Vacuum Furnaces

In 1967 the race to the moon was slowed by the fiery death of the astronauts while they were simulating the flight of Apollo I.

Gene Shrock moved into my camping trailer and began to build drafting boards in an old Laundromat in the little trailer park. Gene did not like to get up in the morning and when in deep sleep he refused to wake up. This proved to be an asset because I could pick up an engineering task from Huntington and allow Gene to work late in the night to have a completed drawing by the morning.

The first contract for the new business was to design the material handling system for scraps and other raw materials for Special Metals. They had not allowed enough area and the building was not high enough for a crane to put materials in hoppers. Henry Venetta, Venetta Engineering, certified the drawings to raise the roof on the building Special Metals had just completed.

The second contract was to install the furnace for Temescal at and the third was to represent the interests of Ajax on the project. Temescal assigned David Arnott in March 1966 to handle their obligations so he became my first day to day customer.

With fifteen thousand dollars borrowed from the Marine Midland Bank the tools needed for the job were purchased. A crew of Mohawk Indians, world-renowned for their high steel building and bridgework, were hired to do the construction work.

Lenny Garrow became the construction foreman and was paid $1 more than the union scale. His crew was mostly Mohawk's but he hired an Irishman as his chief welder.

With a rented a mobile crane the Indian crew did the lifting for all the contractors on a job by job basis. The team always worked faster when we had a firm price and slower when it was time and material. No one ever said a word about that, it just happened. We moved water tanks, set pumps on roofs, tore down old steel structures, and performed any other job where the crane was needed.

The 30-foot high door for the mold chamber at Special Metals was opened by raising it up like a guillotine. Fourteen-inch pipe was used as the framework and inside this was a twelve-inch pipe filled with scrap. Pulleys with steel cables attached to the door and the scrap filled pipes so the counterbalanced weight was about 250-pounds. A small electric hoist did the work with a limit switch at the top stopping the lift. On the first try the limit switch failed causing the 12-inch counterbalance to bottom out. Now 10-tons was on a 500-pound hoist and the cables snapped. Newton's law of physics took over and it made a mess when the door hit the bottom. As with all little mistakes this problem was fixed so even if the limit switch failed it would never bottom out.

Special Metals was responsible for moving the Ajax electrical equipment under the platforms. The work had to be done over a weekend and Huntington wanted a fixed price for this overtime work. I figured that we would need a five-man crew for two days to slide the equipment across the floor on rollers and contract price was based upon that estimate. The crew wanted to go home over the weekend to do some drinking and hunting, so they suggested Friday night would be enough. We were under penalty to have the job done Monday morning.

The crew took the cables and hook away from the mobile crane and rigged slings to fit over the boom. They then drove the machinery into position with the boom clearing the underside of the steel by less than one inch. My foreman confessed that he had eyeballed the space under the platform, but the men measured it. The job was done in less than one hour. The crew was treated to a steak dinner with the time clock running before they departed for the reservation.

By April 1967 enough money had been earned to pay off the bank and buy a new 98 Oldsmobile so Jody could have the Ford on a full time basis. Most of my free time was spent on paperwork required by the government. The payroll paperwork was the straw that broke the camel's back.

Charles Cragnolin was a construction supervisor from Utica working for Huntington at that time. He had an established system for payroll and job accounting and he agreed to join me as an equal partner for the work in Utica. We named the company Cragmet for Cragnolin and Metcalf. We gave ourselves the title of vice president and started looking for a technical president.

Henry Raufer was recruited as a partner and the president of the company. We first met when he worked for Rowan several years earlier. Raufer and Rowan parted company because Raufer did not receive the bonus he was promised and deserved. Rowan knew this and had a soft spot in his heart for Raufer. 440-Raufer.html

In his book Rowan's writer tells us in nauseating detail about the ethics of Inductotherm and its employees. Rowan demanded the maximum from his workers and Raufer gave all he had. The good of Inductotherm was at risk when cash was very short because it was being used in a leasing program and this trumped Rowan's promise to pay a bonus. 403-Provident.html

We were asked for a sealed bid to raise the roof per my original specifications. Part of the bid required that we submit a bid bond. We had to sign away the rights to our homes and everything we might ever own to get a $40,000 bond from the North American Insurance Company.

Cragnolin selected a split nut "C" as our trademark. The ink was not dry on our letterhead when Cragmet attempted to obtain a major contract from Universal Cyclops. The customer would not buy from us due to our lack of capital to guarantee that the company could survive. They awarded the contract to Temescal, including installation. Rowan won a major victory when his induction equipment was specified in the contract.

Part of the original deal between Ajax and Temescal when the Special Metals contract was concluded stated that future business of this type would use only Ajax equipment. Temescal had to return the order to ask that Ajax be specified.

Raufer contacted the management of Brown Boveri and a contract to install their furnaces in iron foundries was a good possibility. I wanted to build vacuum furnaces and Inductotherm was the only sure route.

This situation at Cyclops was the straw that broke the camel's back. Raufer called Rowan with an offer to sell stock in our company. He agreed to a meeting the next day to discuss the situation. Our meeting in Inductotherm's office was brief and the main discussion took place during dinner at the Hideaway restaurant in the Cherry Hill region of New Jersey.

Our offer was to sell seventy percent of the stock for $105,000 was the book value of the company without any mark up for "good will". Our salaries were established at $20,000 and the board was established as three to two in our favor. It was agreed that we could construct bylaws to control ownership and the board with only one restriction. "Inductotherm assures these gentlemen of their proper independence and autonomy in those areas that don't effect the business position or reputation of Inductotherm."

Inductotherm bought a customer because if we purchased Ajax equipment the business position would come into play. In no way did they give up the right to sell to our competitors and extracted a promise that we would not enter the small vacuum furnace business because they were in control of that market selling to other firms.

The agreement is attached along with a portion of Rowan's book where he gets things a little mixed up. 400-Agreement.html

Raufer and Cragnolin drove back to Utica where Raufer structured the bylaws and Cragnolin assumed his duties as the construction supervisor at Special Metals.

Rowan arranged a meeting with the top management at Universal Cyclops in an attempt to win back the order for the thirty-ton furnace. They had already placed the order and were not going to reconsider. Rowan was upset. The main reason for writing the check to buy the stock in Cragmet was history.

Jack Huntington was upset because Cragmet was now a competitor of the company that was installing their job and would not allow me on the site. Construction of the furnace was at a peak so Cragnolin was able to earn almost enough to buy back the local shareholders as required by the agreement.

On June 23, 1967 President Johnson met with Kosygin at Glassboro College in an attempt to thaw the cold war. This would become Rowan University after gave a gift of $100,000.000. A few weeks earlier the United Nations withdrew the peacekeepers from the borders between Israel and Egypt. On June 26, 1967 the Army of Israel concluded the Six Day War with the capture of the Gaza Strip and the Sinai from Egypt. From Jordan they captured the West Bank and the city of Jerusalem. Moshe Dayan told the soldiers, "We have returned to the holiest of our holy places, never to depart from it again." From Syria they took the Golan Heights."

With expanded and reasonably secure borders there was a steady immigration with any person that was a Jew by birth having the right of citizenship. The Jews in the Soviet Union did not immigrate because they, and all other people, were not allowed exit visas. There was no outrage from Israel or America to let the Jews immigrate at that time.

The Metcalf family was already living in a camping trailer in Green Lakes Park near Syracuse with the household goods in storage awaiting a decision on the location of a new residence before school started in the fall. We toured around a little before settling into a camping trailer park near Inductotherm.

In early August Raufer moved his family to Riverside, New Jersey and we rented two rooms in the overcrowded offices at Inductotherm. As part of the rent we had the part time services of a secretary and unlimited telephone usage. From the very beginning we operated the business without support or direction from the sales, engineering or manufacturing of Inductotherm. We decided to use the administrative services of Inductotherm Industries, which Rowan had formed to control his expanding enterprise for accounting and other services to include insurance. I maintained the position of Treasurer and signed all the outgoing checks that included a check to Industries to cover payroll and other administrative costs. The fee for this service was two and one-half percent of gross sales.

Indel (Inductotherm Development) owned all the land and buildings on Indel Avenue. They had a private road between the Mount Holly-Rancocas Road and Woodlane Avenue. Each year Rowan would close this road for a day so it would not become public.

PemFab was getting started and a building for Rancocas Metals was almost complete. Soon there was a small building that was the home of TechTran.

Across Woodlane Road was the blue building and land owned by Consarc with J Wooding in charge with Inductotherm Industries owning 50%. Indel had no ownership position in this land or building.

The new businesses Rowan was building on Indel with minority partnerships were suppliers to Inductotherm with PemFab becoming the sheet metal cabinet producer, TechTran a transformer producer and Rancocas Metals a supplier of copper tubes and aluminum and copper buss bar. The underlying idea was that these companies would also sell to others to keep the overall cost down to Inductotherm.

In September 1967 the Metcalf family moved into a four-bedroom home in a Levitt built town in Willingboro, New Jersey. This comfortable house near a country club was less than $22,000 because other parts of this new city were becoming a black neighborhood and this depressed the selling prices.

Inductotherm used an airport several miles away for a small fleet of aircraft that the sales and service departments used to offer rapid service to the customers. 405-Fleet.html

My first trip on one of these planes was on a cold morning in October 1967 to travel to Pittsburgh to visit Firth Sterling who were looking equipment to produce tungsten carbide. The Inductotherm salesman, Charlie Eckert, used one of the old single engine planes to fly us to Pittsburgh. I had to pull the prop to get him started and because he had landed on fields with stones previously the nick in the prop cut a gash in my hand as I spun it. Just west of Harrisburg we ran into clouds and returned to Morristown were we landed in heavy ground fog. That afternoon we flew on Allegheny Airlines to Pittsburgh for a late meeting.

The accepted way to build this type equipment was to push graphite boats in line through a heated zone. My idea was to use a graphite-heating zone on a slope, so the product, in graphite tubes, would roll down by itself as the furnace was unloaded a tube at a time. Raufer named this furnace the Lazy Dog, because a "slope up" sounded like a "slow pup."

This was the first order that would require drawings for manufacturing with Raufer and myself making the design. We need space in the drafting department where Gene Shrock and two contract draftsmen could work. Inductotherm did not have space but somehow we crammed into space to start the drawings. We were asked to find room for the next job.

We offered Cragnolin's services to build additional offices for the Inductotherm building. Rowan had several hundred acres, but he insisted we build the offices as close to the highway as the local inspectors would allow. He read the local code as allowing from the center of the road. We read them to mean that we should not build within one hundred feet from the edge of the right away. Rowan won his case with the local zoning board, and we measured from the center of the road. Inductotherm allowed us to make a reasonable profit on this construction job and charged us rent at the going rate. The new space was divided between Cragmet and Linemelt.

A recent photograph shows the hanger located behind the houses on Beverly Rancocas road. It was a single floor building when Cragmet built the extension that angles close to the road in late 1967.

Lenny Garrow was running the final stages of the project for Special Metals and Cragnolin was not needed in Utica. After the small building was finished in Rancocas he really had nothing to do.

Cragnolin was living in a good motel in the area and running up bills that were excessive. He was driving my Oldsmobile to Utica because it was better for long trips. He also began to have appointments at the dentist on Fridays, and did not drive back until late Monday.

Cragnolin was not an equipment builder. He was not going to leave a very old house he was rebuilding in Utica, and we were not going to be doing construction work. It was with great pain that we faced Chuck with the facts and the offer to double his investment. He was relieved and allowed us to use the Crag in Cragmet. Raufer contacted the Provident Bank in Philadelphia to find the money so we could pay Cragnolin.

With Rowan's guarantee to purchase the stock the bank gave us each a loan for $10,000. Raufer was impressed with this bank because a vice president delivered the checks in person. Soon all the minority shareholders of Inductotherm understood that they could borrow against their stock.

The West Coast Inductotherm office was very near a company named Certified Alloys that was supplying master metal to investment casting furnace operations that had sprung up like weeds in California. The sales manager, Jess Cartlidge, was away from his office delivering a hydraulic cylinder using an Apache (007 Papa) to one of his customers because Rowan was in a fight with Emory Air Freight and this was the only way that could quickly service this customer.

Many of the small investment casting companies had simple vacuum furnaces called the "shoe box" built by Stokes and Inductotherm. Certified Alloys was losing business to Cannon Muskegon and Special Metals because they could not supply metal melted in vacuum.

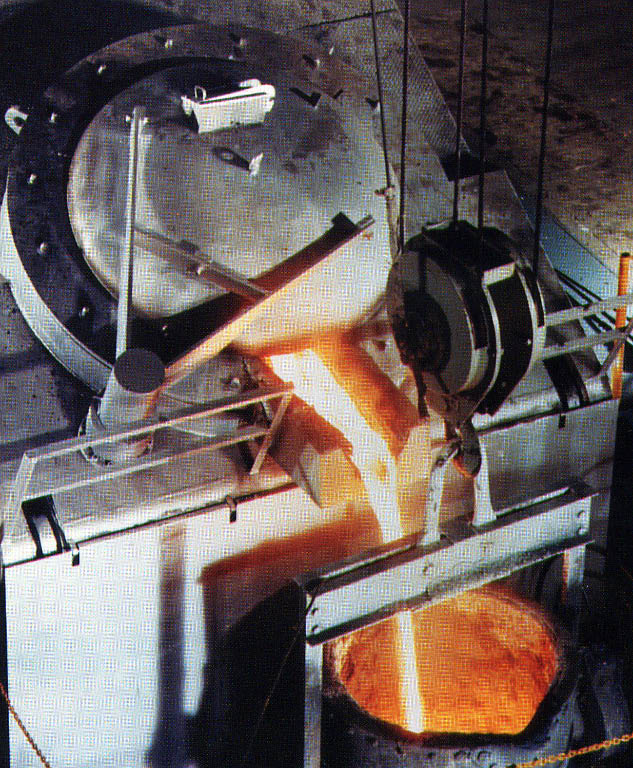

After a few days in sunny California I came home with the first vacuum melting furnace engineering study for Cragmet. This equipment proposed was similar to the Firth Sterling furnace with the exception that the melting furnace was mounted on slides so they could pour multiple rows of ingots on the turntable.

International Nickel Company (INCO), the major supplier of nickel in the world, discovered many new superalloys by their research, but did not have enough capacity to produce them. They decided to buy a 15-ton vacuum-melting furnace in late 1967. They bought a laboratory furnace from Ajax previously that was based on the Firth Sterling job with major modifications by Lona that included a steam jet pumping system.

We prepared our proposal and traveled to West Virginia. Raufer's extensive experience with induction and the fact that I had been a furnace operator put us on the winning path. After lunch we toured the melting shop and pouring floor. Huntington Alloys were the undisputed masters in the field of melting pure nickel and inconel which is a mixture nickel and chromium. My experience with the Anaconda facility that recovered several thousand tons of nickel copper alloy with high carbon was very important in the selling effort.

When we returned to the conference room the idea for what they needed was in my mind. I offered them a design that would copy their air melting and pouring operation by building a house around it using steam vacuum pumps they understood. The power supply would be without generators or trick transformers since it would be single phase 60-cycle taken directly from the power line. The raw material charging machine was based on a hydraulic crane with a telescoping boom. The entrance valve would be vertical and out of "the face of hell". 402-Charger.html

After the flight on a DC 3 to Pittsburgh Raufer and I tipped a few at the bar in celebration of an order we knew was ours before the DC 9 ride home.

We prepared a quick bid at a very attractive price, and won an engineering order for $4,000 to get started.

Inductotherm did not help us at all, since they were already committed to be the sub-supplier to Stokes. Early in 1968 we won the equipment order for the 15-ton vacuum-melting furnace. We were on our way.

The war in Vietnam and building arms to support the MAD policy got in the way of Johnson's social programs. He announced that he would not seek the office of president. Martin Luther King was killed in Memphis.

Brezhnev had just settled into his position of power. Prefabricated concrete sections to build nine story apartment blocks was the main cash outflow for the treasury of the Soviet State. These new small individual apartments were much better than the commune quarters established after the revolution. These new apartments lifted the spirits of the people, and they worked harder toward the day when the promised Communist State would arrive. Lenin had promised that the streets would be paved with gold. The costly arms race put a strain on the financial system, but new productivity offset part of this building economic crisis for a time.

We had an office and a large order and we needed people. A recent college graduate, William Marino, was the first person to interview for the purchasing position. I liked him right away and Raufer hired him that day. We found some draftsmen that had returned home from Ohio where they worked for Ajax. I called Venetta in Ohio and he agreed that three of his people could move to Rancocas to complete this project.

Good fortune smiled on Cragmet when Sid Smith applied for a job. He had worked with Stokes for years and was the engineer that came up with the design for the simple seal that they used on vacuum degassing systems. The patented design was a large rubber section contained between simple bars on the flange of the vessels that held the vacuum. The bee hive section allowed Stokes to build melting chambers that did not have to be machined at much reduced costs. The patent covered only those seals that used a hollow pipe for water cooling of the inner retainer, so we were able to use this method for years to come. Sid was one of the pieces of the "rock" on which our future success was built.

Raufer handled the day to day operations and Marino quickly took over the job of buying all the parts we would need for building the equipment. Raufer hired Marie Raup as our first secretary and she was to become the "mother" of Cragmet in the years to come. Marie was soon to take over correcting my hillbilly dialect into letters to our customers that did not make me look so dumb. She introduced Raufer to a musician friend of hers and Cragmet hired the first and only black man on Indel Avenue.

I maintained all the duties of salesman, idea man, and treasurer of the company. Marino stacked the bills to be paid in piles with checks already cut. The largest pile were those less than $100 which I signed without looking at the documents. With time I began to trust him to the point that only items above $10,000 caught my eye. It was a hard rule that all expense accounts would never cross Rowan's desk.

Accounting at that time was manual because the desktop computer was not in production. We set up a system that did not fit the Inductotherm or the old Ajax system from which it came. Every job was to have a complete set of drawings and the drawing numbers would code sections of the job and the final numbers that described the nuts and bolts would become the part numbers. This was done to reduce paperwork as all purchasing records including source and cost would be kept on these drawings. There was to be no interoffice memorandums written. The idea was that all communications should be face to face and recorded on the drawings for all to see. This system worked well for a time.

Hotchkin and his accounting group were crowded into a small space and were very happy when Cragmet and Linemelt moved into the new quarters. We became friends quickly and he respected that I was the treasurer of Cragmet. He liked the simplicity of our record keeping and the fact that we were doing most of the work of accounting. Most of all he saw that we were also frugal and hard working.

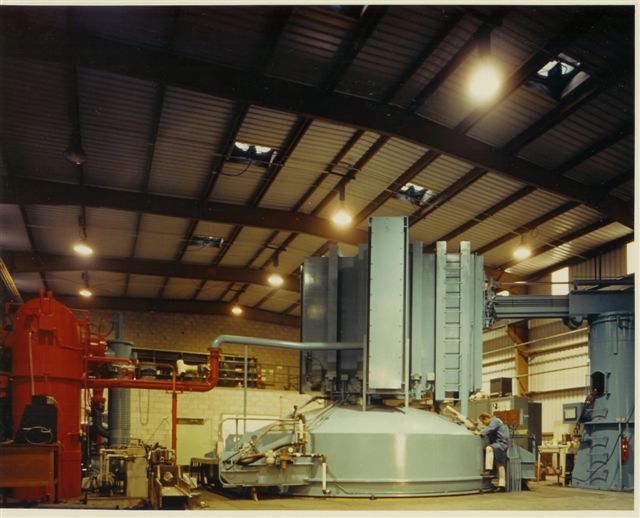

We needed space to assemble the equipment for our customers. We had design talents and a construction crew with tools to build the modest high bay building with a deep pit on one end for assembly of steam jet pump towers. Hotchkin proposed a mortgage structure that would be seven- percent interest and a payback of the principle in ten years. Betty Rowan selected the swamp portion of land for the new building with a selling price of sixty thousand dollars to be added to the mortgage.

We needed fill dirt from the high ground just across the road. The topsoil was quickly removed and the big pans began the job of moving sand. The job was about half done when Rowan called me to his office to meet the irate farmer who rented the land. He had winter oats planted in that ground. Rowan ordered me to stop. I met the farmer outside and paid him three hundred dollars for his seeds and efforts. The cost of hauling in sand would have been at least a hundred times that amount. Rowan convinced me that just a high bay would be expensive to operate and suggested that we should build some low bays.

After our main building was finished we took the crew to Kentucky, just over the river from Huntington, West Virginia. This job was under-priced and we were overrunning our cost projections. The construction site in the field was late, so when we arrived with our heavy equipment we were required to move in before the roof was on. Heavy rains started just as we assembled an expensive crew and equipment. The mud hole was unbearable, and the cost sky rocketed. The project went from bad to worse due to local labor strikes, the quality of our supply and their work.

With the INCO job in deep trouble I needed a person to run the job that had hands on experience and most of all could understand me. We increased out pay offer to Joe Lona in Hazleton to obtain his services as operations manager. He finally agreed when we offered to make him a director.

Ruble needed our office space and asked us to build offices. The Taj Mahal was begun. Shrock built a beautiful building with real stone walls that were two stories high and real one-inch thick black walnut boards for the lobby. Cragmet was in real financial difficulties with the INCO job and was building a structure at least ten times more than it could afford or required.

Rowan had the solution to our problems. We could bill him anything we wanted for the building to make the profits we needed to stay alive. This seemed like a reasonable father son agreement. We would repay the mortgage plus interest in ten years and as stockholder he would have seventy percent of the profit.

As treasurer of the company I should have booked this as a loan and the building and land as an asset. I did not do that but took all the rent as a charge against profits to reduce state and federal taxes. I do not blame Betty or Hank but Hotchkin should have given me guidance. I really do not blame him because he was doing the best for his boss.

Under Sid Smith's leadership a 3000-pound furnace was constructed and installed in California for Certified alloys with a telescoping charger just like the INCO job. For a power supply we used a 500 kW Tri Line.

When I returned from Kentucky after turning the task over to Lona I found that Raufer had outfitted our new executive offices. The lobby had marble tile with deep green carpet in some areas that looked like grass. White ceramic steps circled up toward a skylight in the roof. The walnut wall had a receptionist setting to greet the guests. There were three large offices on this floor. One was for the executive secretary, another for Raufer, and the largest one for me. Raufer showed me my new desk and chair and it was beautiful. I told Raufer that I would consider furniture this expensive to be buried in but while we were on the verge of bankruptcy I would not sit in it.

The purchasing director at INCO understood that we were in serious financial difficulties and offered us an excellent cost plus project to install equipment being supplied by our sister company. Wooding fight with Rowan was at its peak during this period. There was no way he was going to help me, because that would have meant helping Rowan. During our discussions he stated that all his British females, including his bitch dog, were better than American females.

With Lona on the job in Kentucky I had time to finalize the terms of a contract with Certified. The staff in Rancocas was able to turn a small profit on that job but not enough to cover the losses at INCO.

Cragmet had a good set of claims for extras on the INCO job but they needed to be proved. Lona assembled the documents that would be needed so they could process the purchase order change. I realized that would not be enough to save us from bankruptcy so with Lona ready to argue our case I told the assembled group that we were in need and that I was humble.

Raufer restated our plea for more money to the top brass at INCO and won a fifty-percent increase. The plant manager let us quit the project with major problems remaining. His reasoning was that his engineering and maintenance crews would gain from the experience. When asked how he accomplished this miracle Raufer replied; "A hurdle hurdled is a hurdle hurdled."

The INCO job taught me a lot about business. The most fun was learning about the Mohawk Indians by living side by side with the Indian crew. Near the end of the project we flew some of them in the company plane to the reservation in upstate New York. I spent enough time with my Indian friends and the leaders of the tribe to understand just how badly the Indians were treated. I met with the chief and his elders and suggested they open a bank and casino because they were outside US tax laws. They told me the churchgoing Indians would not allow it.

My first flight across the Atlantic Ocean was in the spring of 1968 when the leading producer of stainless steel in Germany, DEW, became interested in using vacuum. During this trip Cragmet received a $10,000 order for a scale model of the 15-ton INCO furnace.

DEW management arranged a meeting with Wilhem Rohn at Heraeus Vacuumschmelze near Frankfort, Germany where the first production size, 4-ton, vacuum furnaces were commissioned in 1928. Rohn told me that these furnaces were converted to 1,000 cycles using a Northrup license in the early 30's so one-ton furnaces could be used for research and production. There was no chance to obtain an order for their new requirements right in the back yard of our main competitor. Records indicate that Germany developed a nickel base alloy containing titanium, forerunner of all modern superalloys, in the middle 30's. This facility could have been used to produce metal for Germany jets during the war.

The International Iron Workers union arranged for two workmen to apply for shop positions during the time we were busy. Soon we found that shop employees had petitioned for an election. Raufer was sure we could win the vote and even sent a driver to pick up one of our shop employees that was working in another location so he could vote. We lost the vote 13 to 12. Two years earlier Rowan had won the vote when his shop employees. Management is not allowed to take any action that could be unfair labor practice, but we were out of work and it was time to layoff workers. I called the union bosses for assistance in deciding who was to be given pink slips. The remaining thirteen workers selected four of their numbers to act as the negotiating team. I explained to the union that it was absolutely necessary that Cragmet management hit the road for new business and reserved Saturday morning for sessions without pay. The central union bosses sent a gentleman with a pile of papers to draw up the contract. This contract did not suit our needs and for sure was not what the employees expected. We were never able to get past the preamble of the contract. They finally went away.

Rowan probably would have kicked us off of Indel if we allowed the Union to establish a foothold.

The race to the moon was paying dividends as transistors were being incorporated into many items. Solid state electronics were the wave of the future. On December 27, 1968 three American astronauts orbited the moon and returned safely

I read my watch. It was 12:35 p.m. by New York time, The day was July 4,1961. This is a clip from Zero to Eighty as his fiction took us to the moon and back.

On March 2, 1969 the Concorde flew using their new carbon-carbon brakes.

At 4:17:40 p.m. EDT July 20, 1969 Americans landed on the moon. Neil A. Armstrong uttered the following words at 10:56 p.m. in the Sea of Tranquility: "That's one small step for man, one giant leap for mankind". The race was over but NASA still had money.